With recent policy changes and financial incentives becoming more common, going green is something that’s on the minds of many companies with fleet vehicles. A fully electric vehicle fleet is an option, but have you considered an auxiliary hybrid solution?

What are the barriers for full electrification?

Some common barriers to the electrification of your fleet are high initial costs, amount of time it takes to replace your current fleet, inadequate charging infrastructure, inexperienced personnel, high voltage safety, power for jobsite, and proven durability.

The cost of full electric

The higher cost of purchasing a new or used fleet of fully electric vehicles is expensive, with the costs almost 2 times that of a traditional vehicle, and that’s not including the infrastructure needs that limit adoption of the technology. While costs are dropping as technology evolves, a fully electric truck is still significantly more expensive than a traditional IC (internal combustion) vehicle. Multiply this amount by however large your vehicle fleet is and the cost becomes a very real barrier.

Inadequate charging infrastructure doesn’t support full electric

Most facilities with small to medium sized vehicle fleets don’t have the necessary onsite charging infrastructure. A fully electric fleet requires up to four times the power needed for a facility designed for diesel trucks. Common power requirements are 480V with a peak demand of 62kW per charger. Often times a significant upgrade (around 5% to 10%) in electrical capacity is needed to charge a fully electric vehicle fleet. Infrastructure upgrades like this require considerable planning and financial investment before an electric fleet is even up and running.

Limitations of using public power are prohibitive to full electric

The public power charging infrastructure also has a long way to go before its able to support fully electric fleets. Most states are pushing towards an electric future where charging stations and large power reservoirs are commonplace, but we’re not there yet. Vehicle charging dependency can vary from low-voltage chargers to high-voltage chargers based on the makeup of your fleet and the amount of vehicles it contains.

Power at Jobsite

Most vehicles will be designed to provide a specific driving range based on the vehicles mass and drive profile. These vehicles do not plan for the unique demands of a specialized work truck and the myriad of power loads needed for the vehicle to provide the work it was designed for. Further complicating the process, the native voltages of 380 VDC or higher will need to be transferred to the teams traditional devices, resulting in more complexity, cost, and safety concerns.

If you’ve considered lithium ion in the past…

It’s worth noting that if you’ve considered lithium ion alternatives in the past you were probably left feeling pretty unimpressed. Current drop-in lithium ion is consumer grade and thus isn’t designed to operate in industrial environments. Unlike consumer applications, industrial vehicle fleets require specialized lithium ion batteries.

Enter Volta’s game changing commercial grade hybrid auxiliary power system.

Volta empowers you

Volta empowers its customers by providing access to the latest in technology and engineering support that eliminates the risk and cost that automakers have spent years and $ billions developing. Skip the R&D, product integration risk and high voltage safety challenge and utilize volta’s scalable, low voltage, high power solution for almost any vehicle platform.

In alignment with automotive-grade performance, Volta systems are designed to meet the specific goals of your application. The system is standardized but allows flexibility across multiple vehicle platforms and scalable upto 96kWh. Whether it’s for a large fleet or a fleet of only a few vehicles, our systems create a lasting experience with the same reliability and flexibility you would expect from shore power.

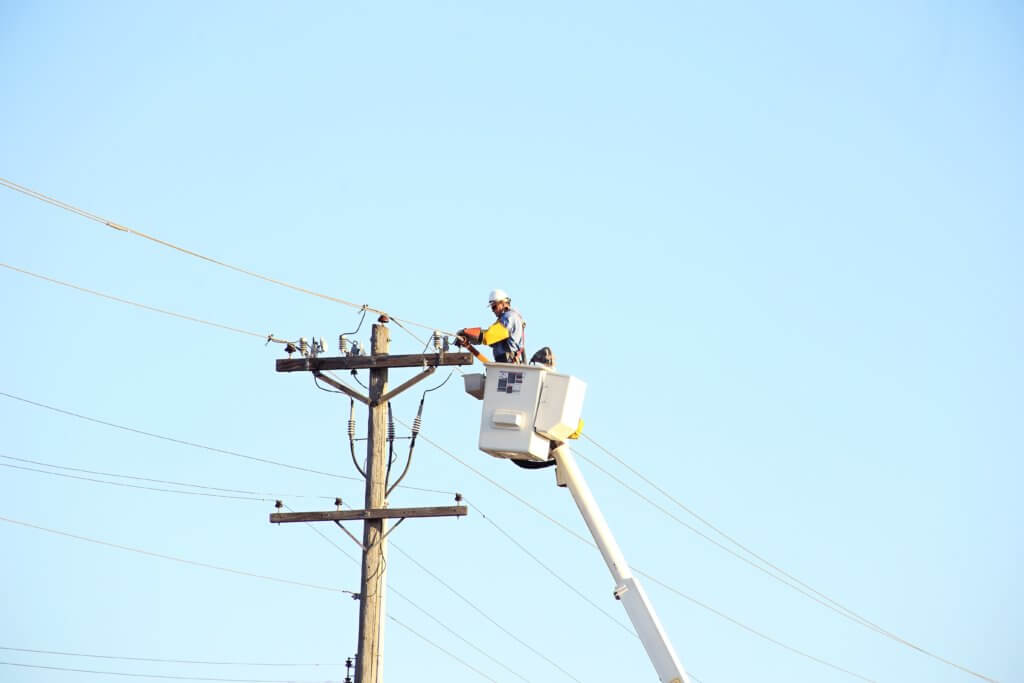

„I’ve been a lineman for 11 years having never worked on an electric truck, and the transition has been very easy.“

Steven Giles: OG&E Service Technician

To see just how seamless a transition it is take a look at how Oklahoma Gas & Electric’s transition to a Volta Power System has gone.

A smooth transition

Our hybrid power system includes a high current alternator that charges the truck while it is running, either in drive or an idle, alleviating the need for an on-site charging source. The system can scale to any needed use case.

Using a scalable approach we are able to customize under-the-hood power generation to match charging needs and deliver any voltage through a system of DC converters and powerful, pure-sine AC/DC inverters including 240V output and 208V or 480V 3-phase service. This allows for a seamless transition from a standard idle based work truck to a Volta powered work truck with no need for special infrastructure.